In the realm of engineering, challenges inspire innovation. In a recent design challenge, Engineering Labs was tasked with creating a service box to house outdoor gear that could be easily assembled without welding, manufactured swiftly, economically viable, aesthetically pleasing, and capable of withstanding the elements. In this blog post, we delve into the key aspects of this journey.

The initial challenge set before us was multifaceted. We needed to create a toolbox that addressed several crucial requirements simultaneously. This challenge provided us with an opportunity to showcase our engineering prowess and show what could be achieved.

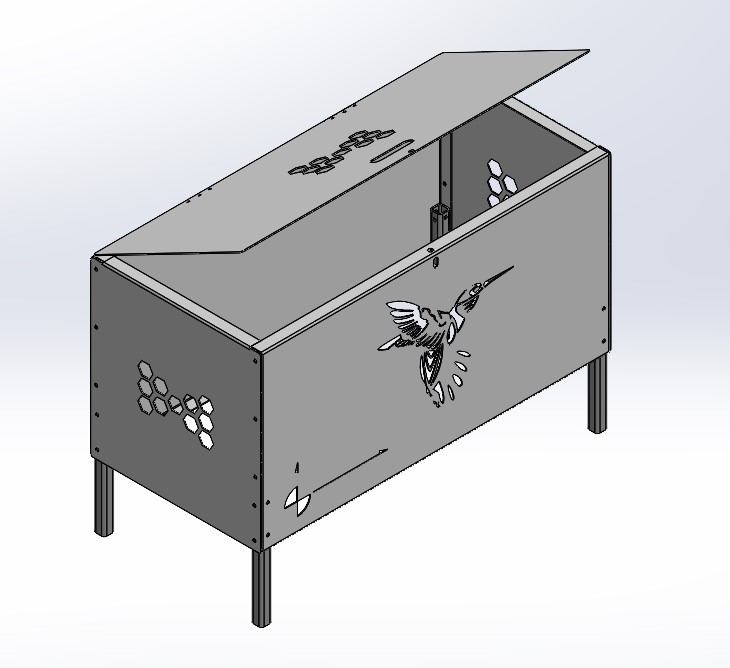

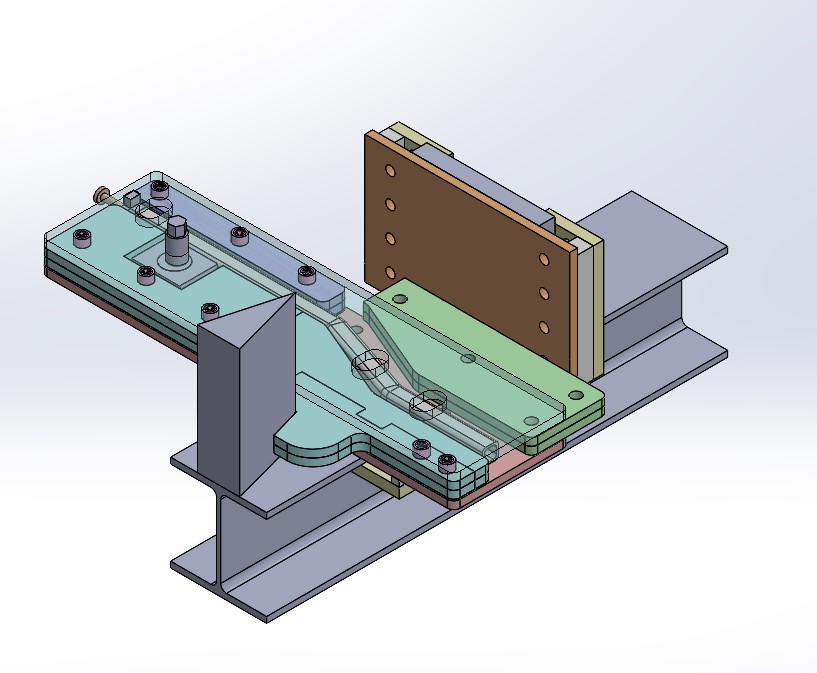

To tackle this challenge, our engineering team opted for modular lasercut and folded components that could be assembled without welding using structural rivets.

when it comes to design, we leveraged our CAD technology to produce the necessary files for seamless communication with the laser cutting and folding service providers. This integration streamlined the production process, ensuring efficient and precise manufacturing.

Furthermore, our design team worked to create an aesthetically pleasing structure by adding some shapes ensuring the design language blended with installation location. The result was a toolbox that seamlessly blended functionality with visual appeal, leaving a lasting impression on our client.

The successful completion of this design challenge highlights the achievements of our engineering team. We have created a service box that sets new standards in aesthetics, and durability. This project exemplifies our commitment to pushing boundaries and delivering outstanding solutions to our clients. Moving forward, we embrace future challenges with the same enthusiasm, confident in our ability to surpass expectations and shape a better world through engineering excellence.