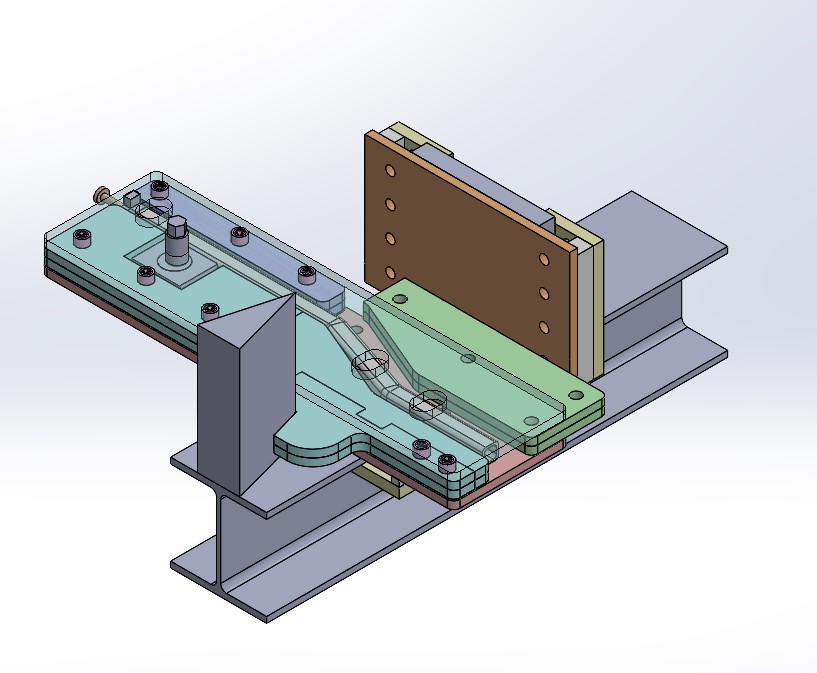

In the realm of engineering, the ability to transform raw materials into precise and functional shapes is of paramount importance. Recently, our engineering company undertook a challenge that demanded precision and innovation: designing a bending jig utilizing a hydraulic ram to bend a square tube into a final product.

The primary challenge we faced was to bend a square tube with reliability and repeatability. Square tubes pose unique difficulties due to their corners and flat surfaces, which can lead to deformation if not properly handled. Our objective was to design a bending jig that would secure the square tube firmly, distribute the bending force evenly, and allow for precise control of the bending angle. This required a keen understanding of material properties, precise calculations, and innovative design solutions to achieve the desired outcome.

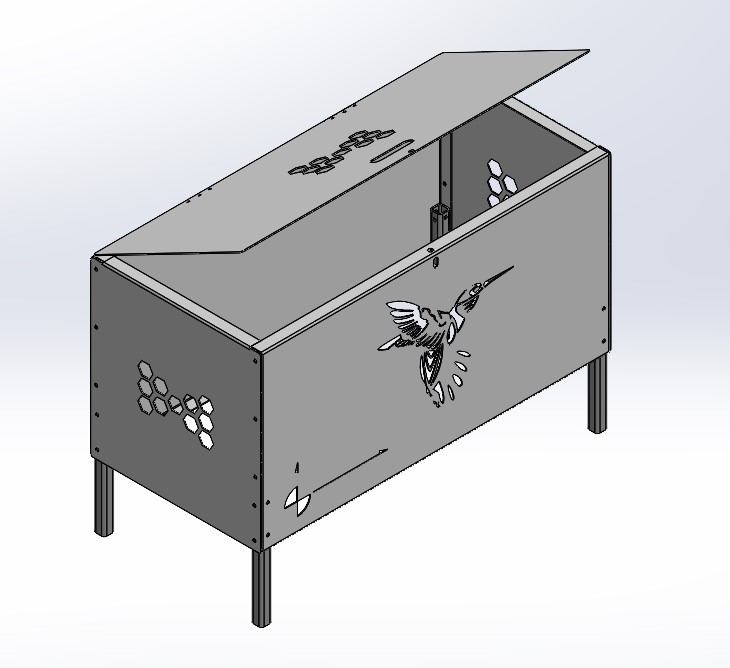

To tackle this challenge, our engineering team leveraged the power of computer-aided design (CAD) to develop a comprehensive and precise design for the bending jig. CAD software enabled us to visualize the bending process, analyze stress points, and optimize the jig's structure. Once the design was finalized, we collaborated with a trusted sub-contractor specializing in laser cutting to translate our CAD files into final components.

Upon receiving the laser-cut components, our assembly process began. The components were carefully inspected, ensuring their accuracy and adherence to the design specifications. We assembled the jig, paying attention to every detail to ensure its stability, durability, and functionality. Through calibration and testing, we fine-tuned the design to provide the desired outcome.

The culmination of our efforts was a successful bending jig which achieved the required outcome in terms of precision and performance. The hydraulic ram, guided by the designed jig, allowed for controlled and repeatable bending of the square tube with minimal deformation and accurate bending angles.